Selecting the right collated framing nails for the pneumatic nail gun you own can be confusing. EZ Fit can help take the confusion out of the selection process. It starts by remembering these three words – Paper, Plastic and Wire. These words refer to the material used by manufacturers to hold the nail strips together (collate). For the most part, and with few exceptions, all paper collated nails will fit the same tools; all plastic collated nails will fit the same tools and all wire collated nails will do the same.

When framing, using the right type of framing nails is just as important as choosing the right type of wood. As any contractor knows, you can’t simply pick the cheapest wood and starting piecing it together. It requires a knowledge of what works best, what can weather the environmental conditions, what will stand the test of time, and so on and so forth. There are tons of factors that go into choosing the right materials for the job. As with the wood, knowing what sort of framing fastener works best will improve the quality of your project as well as how well your frame stays standing.

EZ Fit helps you determine what type of fastener you need to start framing. With our extensive offering of options, it can sometimes be hard to figure out what type will work best for you. Fortunately, EZ Fit has a guide to help you decide. Our gun-fed framing nails come in angles ranging from 20° to 30°. We offer nails that are collated differently to adhere to your individual needs: paper, plastic, and wire welded.

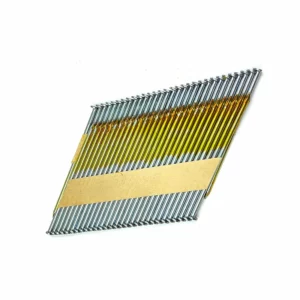

Paper Collated

The same is true of Plastic collated strips. Manufacturers may identify their plastic strips as 20°, 21° or 22°. Like paper strip nails the actual angle of collation makes no difference as it relates to performance in your gun. The same applies to wire collated nails, which are made at a 28° angle. Depending on what region of the country you are in, you may see some 28° paper nails but the majority of all paper tape nails are within the 30-34° range. Over time, fastener manufacturers have specified a “degree” to their nail strips. Paper collated nails are typically 30° or 34° which can be confusing if you are trying to select the right fastener for your tool. However, any strip that is within 4° will fit into the same gun(s). Paper collated framing nails typically run the most expensive, but are the best overall performers. When a nail gun fires, it tears bits and pieces of the collating material from the row of nails. In this case, it is tearing away tiny pieces of paper. Conveniently enough, considering it is paper and not plastic or metal, it results in less mess on the job site. Biodegradable paper means that the small pieces left behind will not harm the jobsite. In addition, the head of the nail will push the down entirely into the wood. This allows proper setting without any additional work and leaves a clean, smooth finish where the nail is.

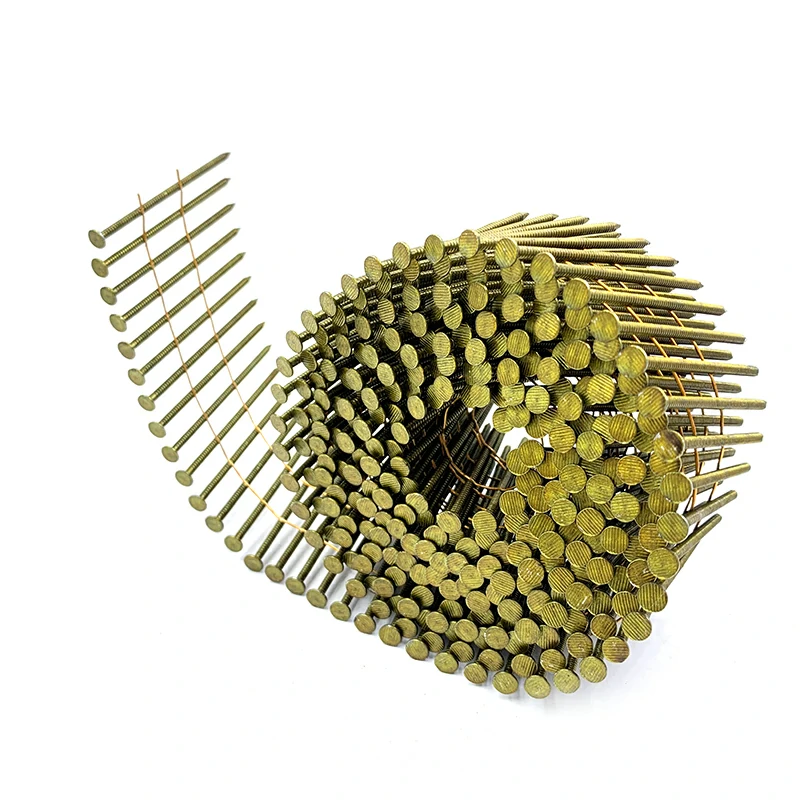

Wire-weld Collated

Alternatively, you can use wire-weld collated framing nails. A piece of wire weld has been tacked to each row of these nails, making them extremely durable. They do a great job when framing outside and can withstand the ruggedness of a typical jobsite. Additionally, these sleeves generally come with more nails per sleeve, meaning less reloads of the gun.

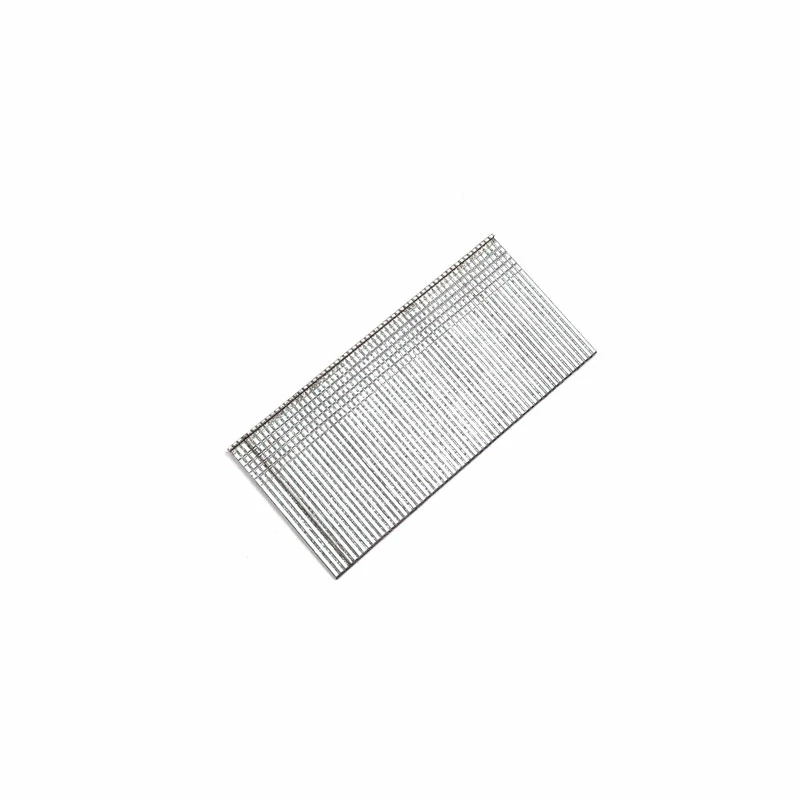

Plastic Collated

The last type of framing nails is plastic collated. These nails are generally the least expensive and fairly durable. They can withstand water damage and are both heat and cold durable making them great for outdoor usage. Plastic collates jam less and aren’t dangerous when expelled from the gun.

High-quality EZ Fit framing nails are designed to work through all major brands of nailers – Max, SENCO, Paslode, Duo-Fast, Hitachi, Bostitch and more. Manufactured in North America, EZ Fit framing nails are available in Paper, Plastic and Wire collated styles and in the lengths contractors require. They are ideal for all your jobsite applications – framing, wall and roof sheathing, decks. Available in Bright and HD Galvanized, EZ Fit fasteners meet or exceed local building codes. No matter what type of framing nail you wind up using, let EZ Fit help match you with what is the right style of framing nail for your job. For more information contact us or check out our easy-to-read fastener guide complete sizes and styles of each of our framing nails.